| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : LB

Model Number : LB

Certification : CE,ISO

Place of Origin : ZHANGJIAGANG

MOQ : 1 SET

Price : negotiation

Payment Terms : L/C, T/T,

Supply Ability : 15 SETS PER MONTH

Delivery Time : 45 WORKING DAYS

Packaging Details : WOODEN BOX

Material : PE

Screw Diameter : 65mm

LD Ratio : 33:1

Warranty : 1 Year

Motor : Siemens

Screw design : Single-screw

Voltage : Customer demand

Automatic grade : Full-automatic

After-sales service provided : Engineers available to service machinery overseas,Online support,Video technical support,Field installation,commissioning and training

Color : Customised

Control : PLC+Touch Screen

Processing type : Extrusion Machine

75-315 mm HDPE PE Pipe Extrusion Making Machine

APPLICATION:

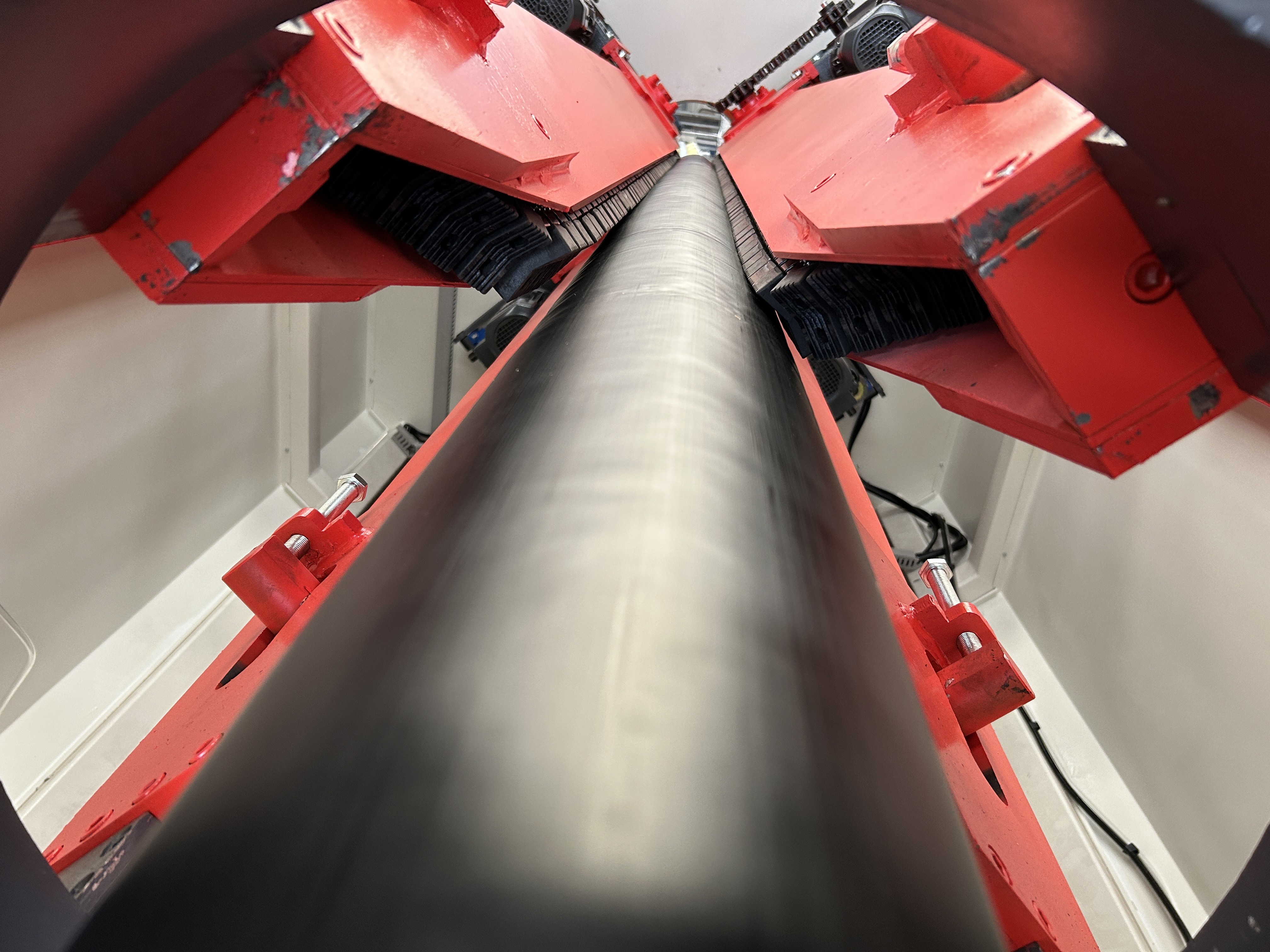

The 75-315 mm HDPE/PE Pipe Extrusion Making Machine is a high-performance production line designed for manufacturing high-density polyethylene (HDPE) and polyethylene (PE) pipes with diameters ranging from 75 mm to 315 mm. This machine is widely used in water supply, drainage, gas transmission, and industrial piping systems due to its efficiency, precision, and durability.

Featuring advanced extrusion technology, precise temperature control, and automatic sizing, this production line ensures consistent pipe quality with excellent strength, corrosion resistance, and smooth inner/outer surfaces. The machine is equipped with a high-efficiency screw design, vacuum calibration system, and advanced PLC control for optimal performance.

PE PIPE PRODUCTION SPECIFICATIONS:

| Model | Pipe diameter | Extruder | Extruder power | Capacity |

| LB-63 | 20-63 | SJ65/33 | 55AC | 150 |

| LB-110 | 20-110 | SJ65/33 | 55AC | 150 |

| LB-160 | 75-160 | SJ75/33 | 90AC | 280 |

| LB-250 | 90-250 | SJ75/33 | 110DC | 350 |

| LB-315 | 110-315 | SJ90/33 | 160DC | 450 |

| LB-450 | 160-450 | SJ90/33 | 160DC | 450 |

| LB-630 | 315-630 | SJ120/33 | 280DC | 850 |

| LB-800 | 500-800 | SJ150/33 | 315DC | 1100 |

| LB-1200 | 710-1200 | SJ150/34 | 400DC | 1350 |

Features of the production line:

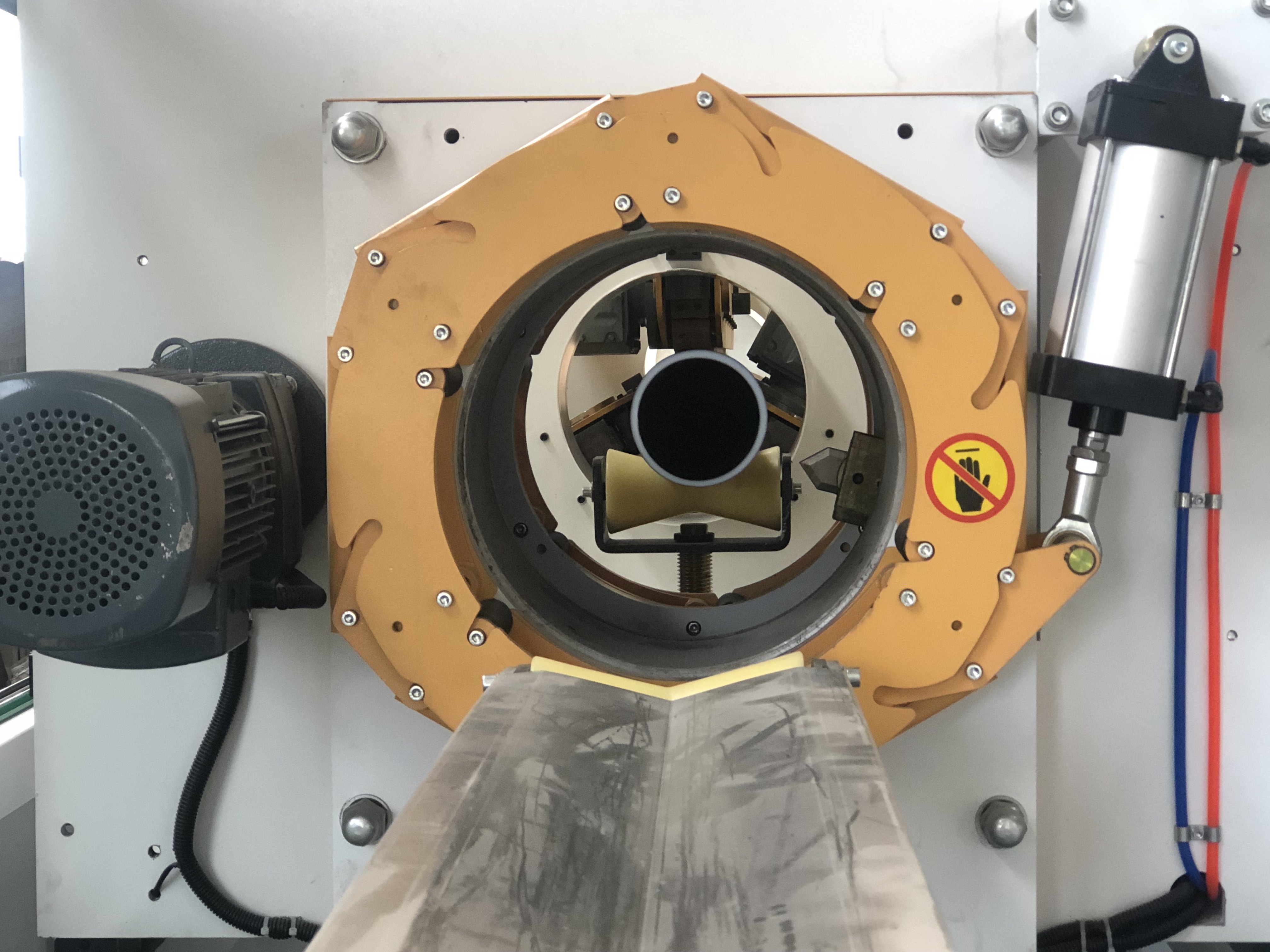

1. The mold adopts spiral runner design, with uniform distribution of each layer and no fusion line.

2.The extruders are driven by servo motors with precise control and stable material output.

3. Cooling water circuit adopts internal and external self-circulation, independent of each other, preventing water from being polluted.

4. The traction cutting is driven by servo motor, and controlled accurately, to ensure that the cut product incision is flat and the length is consistent.

Process flow:

Raw material + additive → mixing → vacuum feeding machine → hopper dryer → single screw extruder → color code extruder → mould and calibrator → vacuum forming machine → cooling tank → haul off machine → cutting machine → stacker

Material Feeding & Mixing

HDPE/PE raw material (in pellet form) is fed into the hopper.

Optional automatic mixing system ensures uniform material distribution.

Extrusion

The material is melted and homogenized in the single/double screw extruder with precise temperature control.

The molten plastic is pushed through a pipe die head, forming a continuous pipe shape.

Vacuum Sizing & Cooling

The pipe enters a vacuum calibration tank to ensure accurate diameter and wall thickness.

A spray or immersion cooling system solidifies the pipe for dimensional stability.

Hauling & Cutting

The pipe is pulled by an automatic haul-off machine at a controlled speed.

A programmable cutting device cuts the pipe to the required length.

Stacking & Packaging

Finished pipes are stacked or coiled (for smaller diameters).

Optional printing or marking system adds product details (size, date, standards).

Quality Control & Testing

Wall thickness, diameter, and roundness are checked.

Pressure resistance and leak tests may be conducted as per industry standards.

Tech Features & Advantages

Automated control, energy efficiency, and adaptability for various PE grades and pipe specifications (e.g., water/gas supply, drainage).

PRE- AND AFTER-SALE SERVICES

• A great wealth of experience,

• A consistent focus on the highest quality

• A complete twin pipe vacuum sizing system;

• Controlled independently unitary structure twin pipe hauling mechanism and synchronous cutting device;

• Optional length set and accurate adaption stacker.

• A highly motivated team

• Sophisticated process technology

• Customized solutions

|

|

75-315 mm HDPE PE Pipe Extrusion Making Machine Images |