| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : LB

Model Number : LB

Certification : CE,ISO

Place of Origin : ZHANGJIAGANG

MOQ : 1 SET

Price : negotiation

Payment Terms : L/C, T/T,

Supply Ability : 15 SETS PER MONTH

Delivery Time : 45 WORKING DAYS

Packaging Details : WOODEN BOX

Material : PE

Screw Diameter : 65mm

LD Ratio : 33:1

Warranty : 1 Year

Motor : Siemens

Screw design : Single-screw

Voltage : Customer demand

Automatic grade : Full-automatic

After-sales service provided : Engineers available to service machinery overseas,Online support,Video technical support,Field installation,commissioning and training

Color : Customised

Control : PLC+Touch Screen

Processing type : Extrusion Machine

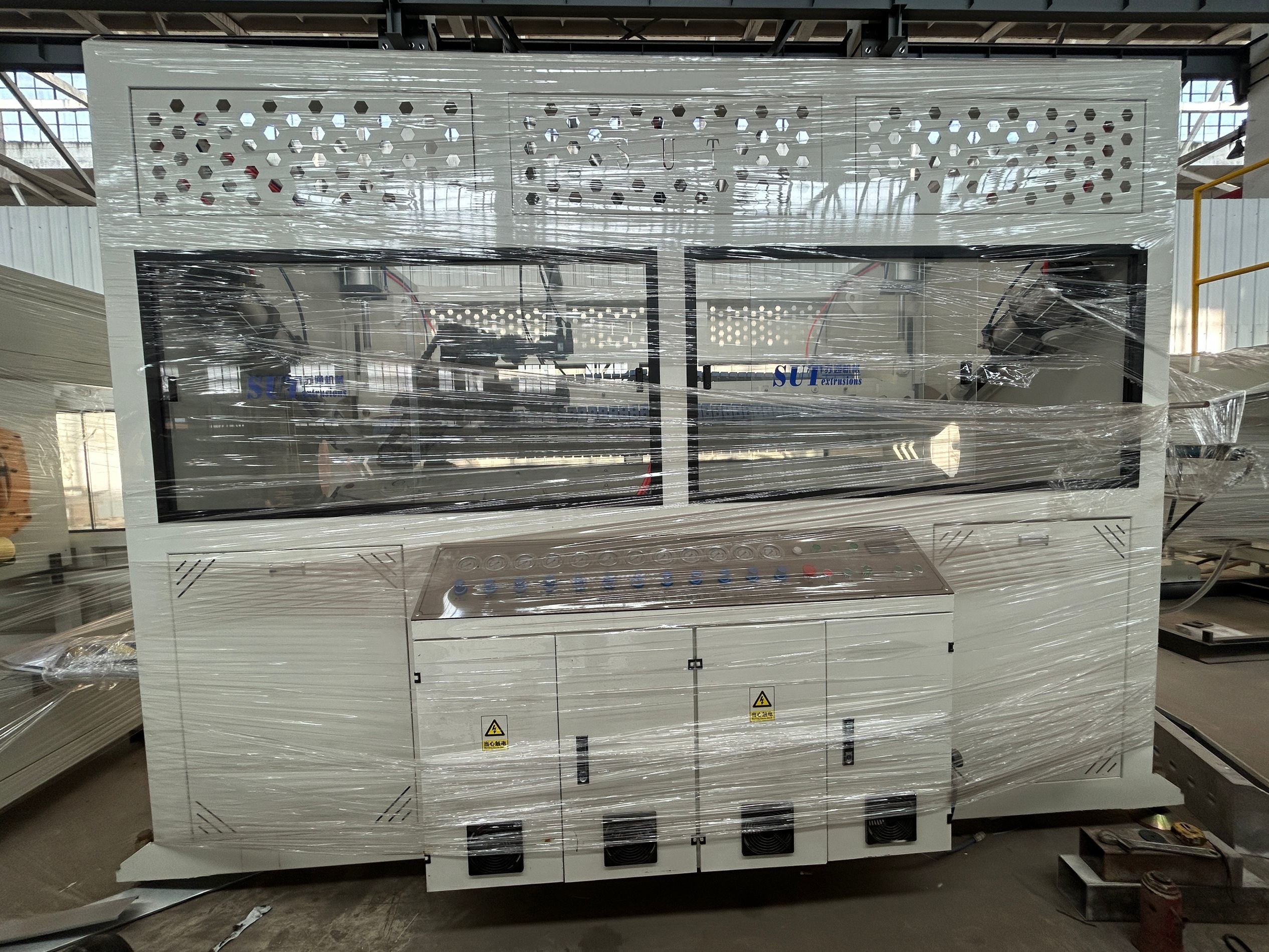

Automatic PE Plastic Water Pipe Extruder Cutter Production Line Machine

APPLICATION:

The Automatic PE Plastic Water Pipe Extruder Cutter Production Line Machine is a high-efficiency, fully automated system designed for the continuous production and cutting of polyethylene (PE) water pipes. This advanced production line integrates extrusion, cooling, calibration, printing, hauling, and cutting into a seamless process, ensuring consistent pipe quality with precise dimensions and smooth surfaces.

PE PIPE PRODUCTION SPECIFICATIONS:

| Model | Pipe diameter | Extruder | Extruder power | Capacity |

| LB-63 | 20-63 | SJ65/33 | 55AC | 150 |

| LB-110 | 20-110 | SJ65/33 | 55AC | 150 |

| LB-160 | 75-160 | SJ75/33 | 90AC | 280 |

| LB-250 | 90-250 | SJ75/33 | 110DC | 350 |

| LB-315 | 110-315 | SJ90/33 | 160DC | 450 |

| LB-450 | 160-450 | SJ90/33 | 160DC | 450 |

| LB-630 | 315-630 | SJ120/33 | 280DC | 850 |

| LB-800 | 500-800 | SJ150/33 | 315DC | 1100 |

| LB-1200 | 710-1200 | SJ150/34 | 400DC | 1350 |

WHAT’S INCLUDED IN A PE PIPE PRODUCTION LINE?

Raw Material Feeding

PE pellets (HDPE/MDPE) are fed into the hopper of the extruder.

A drying system (optional) removes moisture for better extrusion quality.

Extrusion Process

The material is melted in the single/twin-screw extruder at controlled temperatures (160°C–220°C).

The molten PE is pushed through a die head to form a continuous pipe shape.

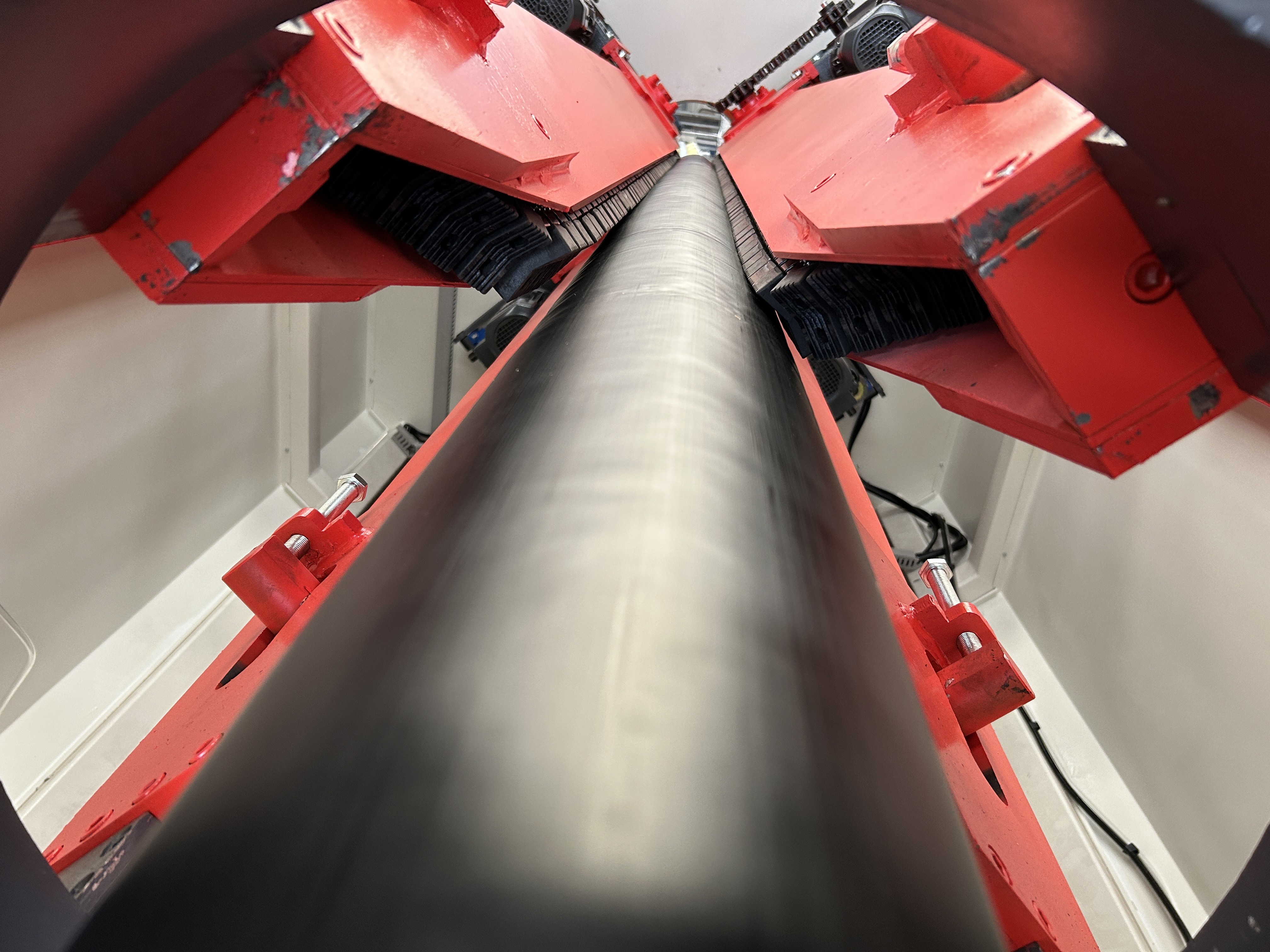

Vacuum Calibration & Cooling

The pipe passes through a vacuum calibration tank to ensure precise diameter and roundness.

A water cooling system solidifies the pipe for structural stability.

Hauling & Cutting

A haul-off unit pulls the pipe at a consistent speed.

An automatic cutting machine slices the pipe into desired lengths (6m, 12m, or custom sizes).

Printing & Coiling (Optional)

Inkjet printers mark the pipe with specifications (size, pressure rating, manufacturer details).

For smaller pipes (up to Ø63mm), a coiling machine can wind them for compact storage.

Quality Inspection & Packaging

Hydrostatic pressure testing ensures leak-proof performance.

Pipes are stacked or packed in bundles for shipment.

Advantages of PE Pipe Extrusion Line

High-Quality Extrusion: Single or twin-screw extruder for uniform melting and stable pipe formation.

Precision Calibration & Cooling: Vacuum sizing tank and spray cooling system ensure accurate diameter and wall thickness.

Automatic Cutting: Servo-driven cutter for clean, burr-free cuts with adjustable length settings.

PLC Control System: Touchscreen interface for easy operation, monitoring, and adjustment.

Haul-Off & Coiling: Optional haul-off unit or coiler for straight pipes or coiled tubing.

Durable Construction: Robust design with corrosion-resistant components for long service life.

Energy Efficient: Optimized heating and cooling systems reduce power consumption.

PRE- AND AFTER-SALE SERVICES

• A great wealth of experience,

• A consistent focus on the highest quality

• A complete twin pipe vacuum sizing system;

• Controlled independently unitary structure twin pipe hauling mechanism and synchronous cutting device;

• Optional length set and accurate adaption stacker.

• A highly motivated team

• Sophisticated process technology

• Customized solutions

Our factory

Our exhibition

Our goods shipping

|

|

Automatic PE Plastic Water Pipe Extruder Cutter Production Line Machine Images |