| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : LB

Model Number : LB

Certification : CE,ISO

Place of Origin : ZHANGJIAGANG

MOQ : 1 SET

Price : negotiation

Payment Terms : L/C, T/T,

Supply Ability : 15 SETS PER MONTH

Delivery Time : 45 WORKING DAYS

Packaging Details : WOODEN BOX

Material : PE

Screw Diameter : 65mm

LD Ratio : 33:1

Warranty : 1 Year

Motor : Siemens

Screw design : Single-screw

Voltage : Customer demand

Automatic grade : Full-automatic

After-sales service provided : Engineers available to service machinery overseas,Online support,Video technical support,Field installation,commissioning and training

Color : Customised

Control : PLC+Touch Screen

Processing type : Extrusion Machine

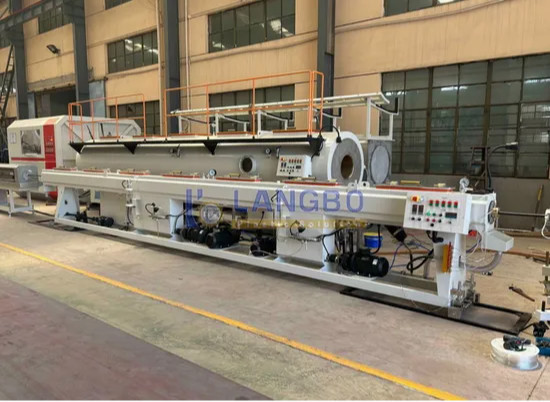

PE Three Layer 32mm 40mm 63mm Plastic Pipe Single Screw Extruder Equipment Line

APPLICATION:

1. PE pipe extrusion machine line is a specialized equipment used for manufacturing high-density polyethylene and polypropylene random copolymer pipes.

2. This machine line is designed to produce pipes of various diameters and lengths, meeting the specific requirements of different applications.

3. The extrusion process involves melting the raw material, such as PE granules, and forcing it through a die to create a continuous pipe shape.

4. The machine line consists of several components, including an extruder, a die head, a vacuum calibration tank, a haul-off unit, and a cutting machine.

5. The extruder is the main part of the machine, responsible for melting and homogenizing the polymer material before it is extruded through the die.

6. The die head determines the final shape and dimensions of the pipe, and it can be customized to produce pipes of various sizes and specifications.

7. The vacuum calibration tank is used to cool and solidify the extruded pipe, ensuring its dimensional accuracy and preventing deformation.

8. The haul-off unit pulls the pipe at a constant speed, controlling its tension and preventing sagging or stretching during the production process.

9. Finally, the cutting machine cuts the extruded pipe into desired lengths, ready for packaging and distribution.

10. PE pipe extrusion machine line is widely used in industries such as construction, agriculture, and plumbing, providing a cost-effective and efficient solution for pipe manufacturing.

PE PIPE PRODUCTION SPECIFICATIONS:

| Model | Pipe diameter | Extruder | Extruder power | Capacity |

| LB-63 | 20-63 | SJ65/33 | 55AC | 150 |

| LB-110 | 20-110 | SJ65/33 | 55AC | 150 |

| LB-160 | 75-160 | SJ75/33 | 90AC | 280 |

| LB-250 | 90-250 | SJ75/33 | 110DC | 350 |

| LB-315 | 110-315 | SJ90/33 | 160DC | 450 |

| LB-450 | 160-450 | SJ90/33 | 160DC | 450 |

| LB-630 | 315-630 | SJ120/33 | 280DC | 850 |

| LB-800 | 500-800 | SJ150/33 | 315DC | 1100 |

| LB-1200 | 710-1200 | SJ150/34 | 400DC | 1350 |

Application of HDPE pipes

1. Municipal water supply, gas supply and agriculture etc.

2. Commercial & Residential water supply

3. Industrial liquids transportation

4. Sewage treatment

5. Food and chemical industry

Working process:

Raw material +master batches → mixing → vacuum feeder→ material dryer → single screw extruder ( small CO-extruder ) → mould → vacuum calibration tank → spray cooling tank ( water tank) → haul-off unit → cutting machine→ stacker

Material Feeding & Drying

PE raw materials (for inner, middle, and outer layers) are fed into separate hoppers.

Optional drying system removes moisture to ensure smooth extrusion.

Three-Layer Extrusion

Three single-screw extruders melt and extrude different layers simultaneously.

The inner layer (smooth for fluid flow), middle layer (reinforced for strength), and outer layer (UV/chemical resistant) are combined in the co-extrusion die head.

Pipe Molding & Vacuum Calibration

The molten pipe passes through a vacuum sizing tank to ensure precise diameter and roundness.

Cooling & Solidification

The pipe enters a water cooling tank for gradual cooling to prevent deformation.

Traction & Length Control

An automatic haul-off machine pulls the pipe at a consistent speed for uniform thickness.

Cutting & Stacking

A programmable cutting machine cuts pipes to the required length.

Finished pipes are automatically stacked or coiled for packaging.

Inspection & Packaging

Final quality checks (dimensions, pressure resistance, surface smoothness).

Pipes are bundled or packed for shipment.

PRE- AND AFTER-SALE SERVICES

• A great wealth of experience,

• A consistent focus on the highest quality

• A complete twin pipe vacuum sizing system;

• Controlled independently unitary structure twin pipe hauling mechanism and synchronous cutting device;

• Optional length set and accurate adaption stacker.

• A highly motivated team

• Sophisticated process technology

• Customized solutions

we will offer customers spare parts at cost prices all life long of the machines.

|

|

PE Three Layer 32mm 40mm 63mm Plastic Pipe Single Screw Extruder Equipment Line Images |