| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : LB

Model Number : LB

Certification : CE,ISO

Place of Origin : ZHANGJIAGANG

MOQ : 1 SET

Price : negotiation

Payment Terms : L/C, T/T,

Supply Ability : 15 SETS PER MONTH

Delivery Time : 45 WORKING DAYS

Packaging Details : WOODEN BOX

Material : PE

Screw Diameter : 65mm

LD Ratio : 33:1

Warranty : 1 Year

Motor : Siemens

Screw design : Single-screw

Voltage : Customer demand

Automatic grade : Full-automatic

After-sales service provided : Engineers available to service machinery overseas,Online support,Video technical support,Field installation,commissioning and training

Color : Customised

Control : PLC+Touch Screen

Processing type : Extrusion Machine

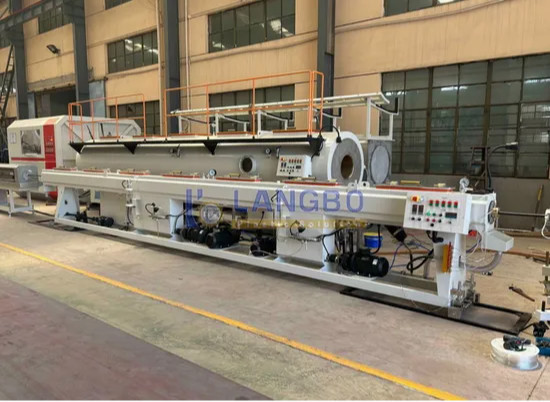

Plastic Small PE Extruder Machine for PE Pipe Profile Granulation Product

APPLICATION:

The Plastic Small PE Extruder Machine is a high-efficiency granulation system designed for recycling polyethylene (PE) pipes, profiles, and other PE plastic waste into reusable granules. This compact and robust machine is ideal for small to medium-scale recycling operations, offering excellent performance, energy efficiency, and ease of operation.

PE PIPE PRODUCTION SPECIFICATIONS:

| Model | Pipe diameter | Extruder | Extruder power | Capacity |

| LB-63 | 20-63 | SJ65/33 | 55AC | 150 |

| LB-110 | 20-110 | SJ65/33 | 55AC | 150 |

| LB-160 | 75-160 | SJ75/33 | 90AC | 280 |

| LB-250 | 90-250 | SJ75/33 | 110DC | 350 |

| LB-315 | 110-315 | SJ90/33 | 160DC | 450 |

| LB-450 | 160-450 | SJ90/33 | 160DC | 450 |

| LB-630 | 315-630 | SJ120/33 | 280DC | 850 |

| LB-800 | 500-800 | SJ150/33 | 315DC | 1100 |

| LB-1200 | 710-1200 | SJ150/34 | 400DC | 1350 |

Process line:

Raw material + master batches→mixing→vacuum feeding →material dryness →single screw extruder→extrusion mould→corrugation forming machine→meter measurer→double winder→finished product inspecting &packing

Feeding & Pre-Crushing (Optional)

PE pipe/profile waste is fed into a crusher (optional step for larger pieces) to reduce size for smoother extrusion.

Extrusion & Melting

The pre-cut PE material is fed into the extruder hopper.

A rotating screw conveys the plastic through heated barrels, where it melts uniformly.

Precise temperature control ensures optimal melting without degradation.

Filtration & Purification (Optional with Filter)

Molten plastic passes through a screen changer/filter to remove impurities (ash, metal particles, etc.).

Strand Pelletizing (or Water-Ring Cutting)

Strand Pelletizing: The melted PE is extruded through a die, forming strands that are cooled in a water bath before being cut into pellets.

Water-Ring Cutting (Alternative): The extruded PE is cut underwater for smoother, more uniform granules.

Cooling & Drying

Granules pass through a cooling system (air or water-based).

A vibrating dryer removes excess moisture for optimal storage and reuse.

Packaging & Storage

The dried PE granules are collected in bags or storage bins, ready for reuse in production.

Advantages of PE Pipe Extrusion Line

1) Simple structure in linear type ,easy in installation operation and maintation.

2) Adopting advanced famous brand components in pneumatic parts ,electric parts and operation parts.

3) Significant high out-put with low energy consumption.

4) Running in a high automatization and intellectualization.

PRE- AND AFTER-SALE SERVICES

• A great wealth of experience,

• A consistent focus on the highest quality

• A complete twin pipe vacuum sizing system;

• Controlled independently unitary structure twin pipe hauling mechanism and synchronous cutting device;

• Optional length set and accurate adaption stacker.

• A highly motivated team

• Sophisticated process technology

• Customized solutions

Our factory

Our exhibition

Our goods shipping

|

|

Plastic Small PE Extruder Machine For PE Pipe Profile Granulation Product Images |